Clothes made from Milk? What is milk fiber material? Clothes made from food? Is that possible? Yes indeed, milk protein, called casein, is used to make innovative fibers that resemble wool. New technologies are constantly being explored and incorporated by the textile industry. This is resulting in innovative textiles such as fabric made from milk.

What is Milk Fiber Yarn?

Waste milk that is not fit for human consumption, is used to produce innovative fibers, called milk fiber or casein fiber. Milk fiber fabric is a blend of casein protein from milk and acrylonitrile,  which is the same chemical that is used to make acrylic. Or it is made from pure casein protein. Milk that is disposed of still contains valuable ingredients, and also offers great potential for technical purposes.

which is the same chemical that is used to make acrylic. Or it is made from pure casein protein. Milk that is disposed of still contains valuable ingredients, and also offers great potential for technical purposes.

Milk cotton yarn was first created in Italy and the USA in the 1930s and was called milk casein. It was made to compete with wool, but the production died during the Second World War. At first the production process used formaldehyde and used loads of water. But this was resulting in a production method that was not profitable.

In the 1930s, Italy was leading the field in making Lanital, a wool look-alike textile that was made from milk. Production started with separation of milk and cream. The cream is used to produce butter, and the skimmed milk is then coagulated to extract casein.

By mixing acid with milk, chemists can extract casein protein, which is similar in appearance to cheese. The casein is dissolved in a liquid that looks like molasses and forced through spinnerets like macaroni. This is put into a chemical bath to harden, which produces fibers. The resulting milk fiber fabric can hardly be distinguished from wool.

Historically, milk fiber yarn had been mixed with a number of substances to provide them with a cotton-like texture and tensility. But these days it is mostly made with a blend of casein protein and acrylonitrile. It is therefore not a true organic or natural fabric, as it is semi-synthetic.

Traditional Production Process of Milk Fiber Fabric

To turn the milk waste into fabric involves a highly technical process. Casein protein needs to be extracted to make the milk fabric yarn. When milk is treated with acid, casein is obtained. Different sub processed are used and these are the main two production processes. Both would have a first step of obtaining the waste milk.

- Milk is skimmed to remove the fat and then de-watered and fermented. At this point it is similar in appearance to milk based protein powder.

- Casein fiber is extracted – casein coagulates as a curd, which is washed and dried and then ground to a fine powder. The powdered milk is dissolved and purified to remove any substances that are not casein.

- Casein is then dissolved in a caustic soda solution and allowed to ripen until it reaches a certain viscosity. It is then filtered and de-aerated.

- The spinning solution is then wet spun by extruding it through spinnerets into a coagulating bath.

- The coagulating bath is made up of 2 parts sulphuric acid, 5 parts formaldehyde, 20 parts glucose and 100 parts water. The filaments coagulate in a manner similar to viscose filaments.

- The fiber then has to go through a chemical treatment to harden it. Formaldehyde forms the basis of most hardening techniques. So as the filaments leave the coagulating bath, they are collected together into a tow, and steeped in the formaldehyde solution. At this stage the filaments are subjected to drawing.

- The next step is to wash and dry the tow and it is then mechanically crimped, before being cut into staple fiber. Casein fiber is almost entirely produced as staple, tow or top.

Alternative Production Method

This is another process which is similar, but with slight variations and involving fewer steps and chemicals:

- Milk is fermented, then skimmed to remove any fat and dewatered.

- Casein fiber is extracted and the powdered milk is dissolved and purified. Any substances that are not casein, are removed.

- Powdered casein is immersed in the alkali to make a solution and passed through spinnerets.

- Solution is immersed in sulphuric acid to remove the alkali.

- Fibers are then stretched and spun into milk fiber yarn.

- Then tanned with aluminum salts and formaldehyde to turn it into a usable textile for clothes made from food.

Modern technique

Because of the toxicity of formaldehyde and the harmful effects of the other chemicals, the production process has been changed.

The modern method of producing casein fiber goes through a process called graft co polymerization. This is chemically grafting the pure casein to acrylonitrile. It doesn’t entail the use of formaldehyde, but acrylonitrile is also toxic and carcinogenic, so still a chemical that we want to avoid.

Milk fiber fabric made in China is normally made with acrylonitrile, so it can still not be classified as eco friendly or sustainable.

A new process which is more eco friendly and does not use formaldehyde or any other chemicals, has been developed by a German company called QMilch GmbH.

Who is QMilk?

QMilk was started by Anke Domaske, a microbiologist, after searching for clothing that had not been treated with chemicals. Milk proteins came to her attention. But because the original textile process that was used in the 1930s was complex and involved various chemicals, she started QMilk as a classic start-up company in a kitchen.

QMilch GmbH was founded in April 2011 and there are now a group of companies that are involved in the development and production of bio polymers. These are based on milk proteins and other natural and renewable raw materials.

The German fabric called QMilk is made from milk fiber yarn, using waste milk that is not fit for human consumption. Milk would normally be obtained from a dairy. QMilk has developed a process that is 100% natural and uses renewable resources. No plasticizers, solvents or chemical cross linkers are used. The fiber is home compostable and will break down and biodegrade in a few months in the environment.

Eco friendly QMilk Procedure

QMILK is a patented, specially designed production process. Part of the process involves:

- heating the casein powder to 80°C in a meat mincing type of machine,

- adding natural ingredients like zinc and beeswax.

- Fibers come out in strands and is then spun into yarn.

Because it is a patented process, no more details are available on the individual steps to make milk cotton yarn. So no formaldehyde is used and a particular level of cost efficiency and minimum CO2 emissions are ensured. It is 100% natural, soft and smooth like silk. It is skin friendly and meet the requirements of innovative material developments.

QMilch received the Green Tec Award in 2015. And QMilk fiber has also passed OEKO TEX standard 100 green certification for international ecological textiles. It is answering the call for sustainable natural fibers and it opens up exciting new possibilities for innovative textiles.

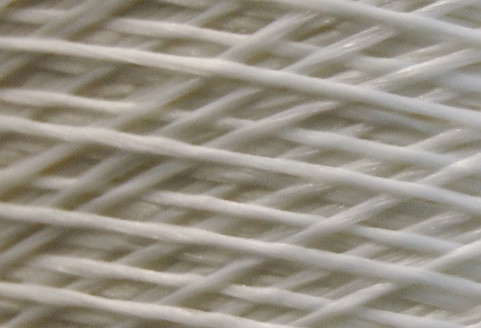

You need about a hundred pounds of milk powder to make three pounds of milk fiber. The fibers are white, fluffy and springy with a pleasant odor. The innovative fibers can be dyed using acid, reactive or cationic dyes.

Applications of QMilch Fibers

QMILK is a protein fiber and an ideal fiber for direct contact with the skin, as it feels like silk to skin. QMilk fibers are free of these harmful materials that are often present in textiles and products:

- isocyanate and halogens.

- solvents

- hazardous plasticizers

- silver, zinc oxide and triclosan

So what is milk fiber material used for? QMilk fibers have fashion applications and technical applications in hygiene and medicine.

1. Fashion applications of QMilch Fibers

QMilk can be combined with any type of wool, but can also be spun with cotton, cellulose or other natural fibers. It can be used as an alternative to cotton or silk. But it can be combined with silk and cotton to create a smoother texture. Milk cotton yarn is perfect for underwear and lingerie, because of the healthy and bacteriostatic nature of milk fiber.

Apart from being good for underwear and intimate apparel, it is also used for socks, household textiles and clothing that would be made from wool.

The milk fiber fabric is compostable, has a silky touch, is natural, thermobonding, temperature regulating and flame retardant. It is naturally anti-bacterial and hydrophilic. QMilk is the only natural fiber that has thermo bonding properties. It can therefore replace conventional plastics and resins as a binder.

Bonding and stabilization is done through pressure and thermal treatment to 100°C. So natural fiber products like linen and hemp, can remain 100% natural. It can be considered a “green” product, as no formaldehyde or other chemicals are used.

2. Technical Applications of QMilk Fibers

Milk fiber can also be used in non-woven applications like toilet paper and baby wipes.  QMilk wipes meet the demands for “flushable”, as it dissolves in water without leaving any residues. So it will not affect the infrastructure of the sewage system.

QMilk wipes meet the demands for “flushable”, as it dissolves in water without leaving any residues. So it will not affect the infrastructure of the sewage system.

QMilk biopolymer is a 100% natural plastic which meets the requirements of a bio-plastic that can be composted at home. Casein has excellent barrier properties, making it suitable for applications in the food industry. QMilk plastic could replace plastic made from petrochemical materials, making these innovative fibers eco friendly.

Related post : Innovative textile solutions for vegans

3. QMilk Beauty Applications

QMilk cosmetics uses microbeads, which is a natural material that can be used in skin care. The milk fiber contains 18 amino acids, which is beneficial to human’s health. It has the function of nourishing and taking care of the skin. Milk fiber has a pH of 6.8, which is the same as human skin, making QMilk beauty products compatible with your skin.

It is made with the casein powder found in milk. Organic oils and milk proteins free of alcohol and glycerol. It can be used for deep cleansing, as it stimulates cell renewal and collagen formation of skin. QMilk also acts as a powerful anti-oxidant and has an anti-inflammatory effect.

QMilk microbeads produce a slight peeling effect where old skin cells are removed, without any harm to the healthy skin underneath. Circulation to the skin is also stimulated, leaving your skin with a youthful radiance.

Properties of Milk Fiber Fabric

Because it is a regenerated protein fiber, milk fiber yarn reacts like wool and has many of the properties of wool.

- Milk cotton yarn is both comfortable and permeable.

- It has a soft, warm handle and is resilient like wool.

- It appears so similar to wool, that the difference can only be established with a burn test with wool.

- Naturally antibacterial and high hydrophilicity.

- Natural fiber with thermo-bonding properties and provides good thermal insulation.

- High moisture wicking abilities, so it wicks moisture away from the skin.

- Can be washed on warm.

- Readily absorbs moisture and fibers become soft and swollen.

- Milk fibers loose their strength when wet, so handle it gently when wet and dry it flat.

- It is easily damaged by alkalies and mildew, so don’t keep it damp.

The Future of Milk Fiber Yarn

Worldwide production of milk cotton yarn is currently minimal. At the moment clothes made from milk is expensive, so it has a limited market. Fabric that QMILK makes cost about forty times more than normal cotton. If you are looking at vintage clothing, there were different brands like Aralac, Merinova and Lanatil.

Using milk fiber reduces the milk waste that is generated by dairies. Two million tonnes of milk is discarded each year just in Germany alone. So just imagine the global waste.

Scientific advances are also helping that companies are experimenting with the fabric. Milk waste offers new business opportunities to develop local textiles and an apparel industry with clothes made from food. By using waste, the negative environmental impact of the milk industry can be reduced.

The main drawback at the moment is the high cost. If the cheaper production process is used, it means that carcinogenic chemicals are used, which we all want to avoid.

QMilk is sustainable and eco friendly, but not suitable for vegans as the milk fibers is derived from animal protein. Milk fiber yarn for making your own projects is available at this link on Amazon.

If you have any question about what is milk fiber material, or comments about milk fiber fabric or the innovative fibers from QMilk, then please leave them below and I will get back to you.

Photo credits QMilch

Hi, I thank you for this article and all the information. My hands up to you and those that are taking action in this direction for the good of all. I am very passionate about the manufacturing processes and the effects that they have on Mother Earth and her inhabitants. I was wondering if you could tell me if QMilk is currently selling wholesale yarns made using this method? I will as well reach out to the company. I thought perhaps if you knew of hand that would be great. Thank you, Katherine

Hi Katherine, thank you for reaching out. It is best to contact QMilk directly to get the latest information on wholesale and methods used for wholesale yarns. All the best, Liné

I just discovered milk fiber and was wondering what type of dye works best with it? I’ve tried fiber reactive dye with soda ash as a mordant, which takes well mostly but bleeds when it’s wet. I even tried using a dye fixer, but it still bleeds when wet. I tried using acid reactive dye, since it’s a protein, and that doesn’t work at all. Are there any other suggestions?

I do not have personal experience of dyeing milk fiber, so would suggest you contact the manufacturers of milk fiber directly to ask for their suggestions. You could try to wash it in salt water, as salt also helps to “fix” color. I hope this helps and please let me know if you find a suitable solution.

Marvellous post!!!

Thank you for your kind comment. All the best, Liné

Hi. I am looking to buy milk fiber in food grade. Could you please help me to find?

Hi there, I would suggest you contact QMilk, who make milk fiber, and ask them. I hope it helps. All the best, Liné

Hi! Can you recommend suppliers of milk fabric (100% organic) with qmilk for clothing? I’m looking for some sources in Europe or the US to explore using to apparel/fashion brand.

Hi there, if you want to use Qmilk specifically, then I would suggest you contact Qmilk direct to find out who they supply their fabric to and hopefully they can supply you as well.

Hi! Can you recommend suppliers of milk fabric (100% organic) with qmilk for clothing? I’m looking for some sources in Europe or the US to explore using to apparel/fashion brand.

Hi Kelly, I suggest you contact Qmilk to ask if they can supply you with their fabric. I hope this helps.

Nice Article ??? ??

Thank you and you are welcome

I had no idea this was possible!

And yet it goes so far back, lol.

I’ll be showing my kids this tomorrow as I’m sure they’ll be fascinated to learn what I’ve just learned.

The best thing I’ve taken from this is the sustainability of using waste milk in such a fashion, once the processing is brought down this seems very viable as an eco-alternative.

Love the site, thanks for the info!

Tony

Hi Tony, it is indeed awesome that an agricultural waste product can be used to make milk fiber yarn, and as long as the QMilch process is used, it is eco friendly.

I have never heard of milk fiber yarn and I find this fascinating. To see it was discovered back in 1930 is a surprise to me. It is always an interest to me how things are made when it comes to products that are discovered from something that might have been on our table. Not letting things go to waste and giving it a valuable use is really something great.

The Eco friendly Qmilk process looks so much better and I am glad they no long use Formaldehyde. I love that our world is looking for natural ways to make our clothes that touch our skin to be healthier for us and our environment. The Qmilk skin products I would be interested in reading more about. This is a great article and I enjoyed learning about Milk Fiber.

I am pleased to hear Terri that you enjoyed learning about what is milk fiber yarn. It is indeed great that a waste product can be used for clothes made from food. If you contact QMilch, they would be able to tell you more about the availability of their skin products and this is the link to their website.

Hope this helps, Liné

Wow, this is absolutely fascinating! I knew casein as a great slow release protein but i never thought it could be used as a textile! I am very curious as to how these materials feel against the body.

Do you know if there is a limit to their use? For example could it be used to also make a canvas like material? And how soon do you think this sort of technology to become widespread?

These are quite exciting times we live in!

All the best

Milk fiber fabric has a silky, soft and luxurious feel to the skin. At the moment it is not used for making heavy duty textiles like canvas, but who knows, maybe in the future these innovative fibers will be used for more applications.

I am impressed! I never heard of milk fiber yarn before. I had no idea that these items were made from such a thing as milk fiber yarn.It’s very interesting that clothes are made from this.I love to read about how things are made and this was certainly no exception. It’s also interesting to learn that QMilk is not suitable for vegans since it’s made from an animal product.Great article!

It is indeed great to learn that a waste product can be used to make milk fiber yarn, resulting in clothes made from food. Cotton milk yarn is still expensive, but with technological advances being made on a regular basis, it will hopefully become more widely available and affordable.

I am impressed! I never heard of milk fiber yarn before. I had no idea that these items were made from such a thing as milk fiber yarn.

It’s very interesting that clothes are made from this.

I love to read about how things are made and this was certainly no exception. It’s also interesting to learn that QMilk is not suitable for vegans since it’s made from an animal product.

Great article!

Making milk fiber yarn is a great way of using a waste product and clothes made from food can then be produced.

What an eye opener, from milk to fabric, who would have known!

This Eco World of Science, and the mind we have, can cause us to be so creative with the thing around us, going Green is one way I would say for this eye opener.

From the making of cosmetic to beauty product that consist with anti-oxident, and anti-inflametory effect leaving you with youthful skin.

I dont think I would like my Clothing made with formaldehyde, but the process and what they are able to make with milk.

The Process none as Casein was made to compete with wool, a wool look alike textile that was made from milk, by mixing acid and formaldehyde this semi synthetic look fabric was made.

The bath tissue, and the bio plastic bags that desolve, sounds great, but it takes so much to make it is it worth it?

This was great rescearch, who Knew!

Great to know that you have learnt something from What is Milk Fiber Yarn. Amazing to find that clothes made from food is indeed possible and using a waste product, makes it even better. Thankfully formaldehyde is no longer used in the production process of milk fiber fabric and the QMilch production process is eco friendly, although still expensive.

This is amazing! I had never heard of milk fiber yarns until I was doing some research for sustainable fibers. I had no idea you could do this with casein which I know about just as a type of protein in the fitness world. How does these fibers hold up to washing?

Hi Tony, milk fiber yarn can be washed in the same way as wool and then dried flat, just like a wool garment. Hope this helps, Liné

This quite a technical and chemical process that requires one to be conversant with molecular/industrial chemistry and process flow to start with. Well articulated and informative as well. I think I like it because it guides one how fiber is produced from milk and the uses of the end product. I wish I could implement it here in my country, do you have a diagram showing the main process flow and references?

Hi Joel, I did find a diagram showing the original method with formaldehyde and other chemicals, but because the QMilk process is patented, that information is not readily available. You could contact QMilk, this is the link to their website, and maybe talk to them about implementing it in your country.

Hope this helps and all the best, Liné