What is leather?

Leather comes from the skin of animals and reptiles and the basic component is rawhide.  If leather is not treated, it will become stiff and fall apart as it is biodegradable. It will also be attacked by insects and other creatures that find leather a tasty snack.

If leather is not treated, it will become stiff and fall apart as it is biodegradable. It will also be attacked by insects and other creatures that find leather a tasty snack.

This means that leather has to be “cured” before it can be used for garment and footwear production.Many years ago the tanning process of leather often involved the use of smoke, as well as vegetable tannins, salt, urine and animal faeces or even animal brains. So this was a very smelly and messy affair, so most tanneries were situated outside towns.

Although leather also comes from ostriches, snakes, crocodiles and other animals, most leather is derived from cattle, so I will focus on those processes.

In this post we will be looking at the tanning process of leather, the environmental impact of the leather industry and what is eco friendly leather. The process of making leather involves many treatments to preserve it and make it usable.

Is leather environmentally friendly?

Leather manufacturing does have a big environmental impact. There is very heavy use of polluting chemicals, like chromium salts, in the tanning process. Leather can contain high levels of toxic chemicals, so when it is in contact with skin, it can cause skin irritations and in severe cases cancer. Finished leather products like shoes and gloves are in direct contact with the skin.

Air pollution is high due to solvent vapours that are used during dehairing and deliming. There is also a huge strain on waterways due to chromium and sulfide pollution. A chrome tanning facility wastes nearly 15,000 gallons of water and produces up to 2,200 pounds of “solid waste” (e.g., hair, flesh, and trimmings) for every ton of hide that it processes.

Modern tanning is still a messy and smelly affair with a ton of extra energy, water and toxic chemicals thrown in. The process is so toxic that many old tannery sites cannot be used for agriculture. Tanneries not only often poison the land they are situated on, but also the waterways into which they discharge effluent.

The environmental impact is in the manufacturing, so let’s have a look at how leather is made.

Process of making leather

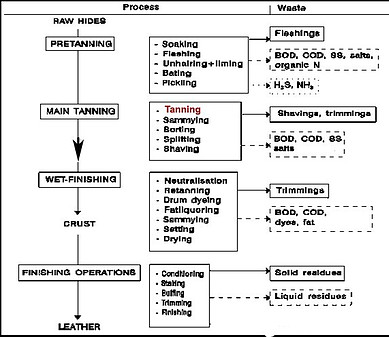

The principal methods of making leather haven’t changed that much over the years, but that doesn’t mean it is easy. The process of making leather is a surprisingly complicated and lengthy process and to get a piece of leather ready for use, takes ten to thirty working days! Leather manufacturing goes through three sub processes to cure the leather:

- Preparatory stages.

- Tanning process of leather

- Crusting

1. Preparatory Stages

According to the type of leather, the processes can vary slightly but all leather will go through the three sub processes.

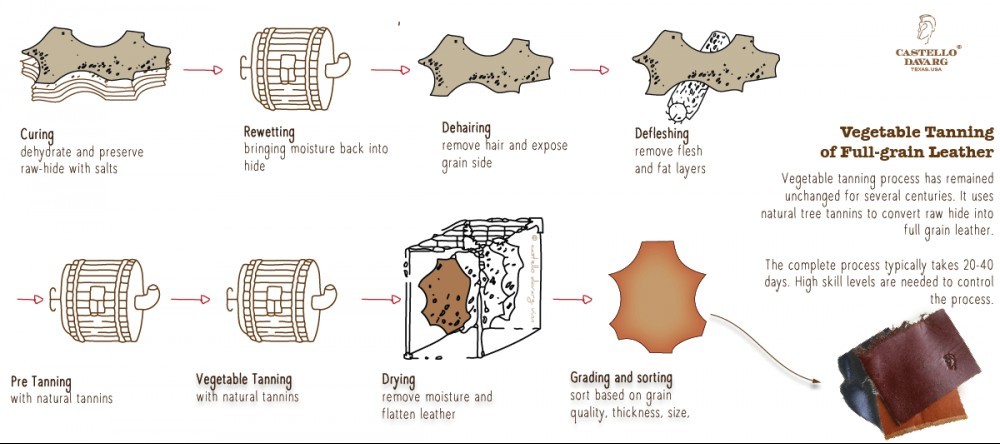

- Hides are first prepared by curing them with salt. To stop the raw hides and skins from deteriorating, they must be preserved before the leather-making process can begin. Apart from using salt, other methods of preservation include chilling, freezing and the use of biocides.

- The cured hides or skins are then soaked in clean water to remove the salt. Soaking can be from several hours to several days. This allows the hides to reabsorb any water they may have lost in the curing process or during transportation. It also helps to clean them of salt and dirt.

- Liming is the process where the leather is soaked in an alkali solution. It is done in a drum and it is to remove the hairs and epidermis from the hides and also proteins and natural fats and grease. This process normally takes about eighteen hours for cattle hides.

- Painting is a method by which wool can be removed from sheepskins using a sulfide based mixture.

- The step after liming is fleshing. The pelt is passed through a machine to remove fleshy tissue from the flesh side. If the hides are thick, they may be split into layers at this stage or after tanning.

- Deliming is the next step. Acids are used and these could be weak acids like boric acid, acetic, formic, lactic acid, phosphoric acid and carbonic acid. Strong acids like hydrocloric acid and sulphuric acid have limited use. The principal purpose of deliming is to gradually neutralise the alkali in the pelt, thereby avoiding rapid changes in the pH level which could lead to distortion or disruption of the tissues. If deliming takes place over a long period, it can greatly improve the removal of any remaining lime, scud (miscellaneous debris) and residual components which were broken down during liming.

- Bating is based on the use of enzymes and completes this process so that the pelt is flat, relaxed, clean and ready for pickling and tanning.

- Most tanning processes require the pelt to have a low acid level, so through pickling, a weak acid and salt solution is used to bring the pelt to a low acid state. Stronger pickling solutions are used to preserve pelts so that they can be stored or transported in a stable form over periods of several months.

- Degreasing involves solvents or water-based systems that are used to remove excess grease before tanning.

2. Tanning Process of Leather

Tanning converts the protein of the raw hide or skin into a stable material and permanently alters the protein structure of the hide.  This means that the leather will not putrefy (rot) and is suitable for a wide variety of purposes. Tanning materials form cross links in the collagen structure and stabilise it against the effects of acids, alkalies, heat, water and the action of micro-organisms.

This means that the leather will not putrefy (rot) and is suitable for a wide variety of purposes. Tanning materials form cross links in the collagen structure and stabilise it against the effects of acids, alkalies, heat, water and the action of micro-organisms.

Tanners are highly trained in what they do and tanning is the next step that tanneries have to do to turn hides into leather. The three main tannages are 1) mineral tanning using chrome, 2) vegetable and 3) aldehyde. Tanning is done in a barrel that slowly turns to expose the leather to the tanning materials.

- Mineral or chrome tanning is the most common tanning process of leather. A heavy metal, chromium, is used in the form of basic chromium sulfate. Chromium is bio accumulative, meaning it can build up in an organism over time.

- Vegetable tannages : Various plant extracts produce brown coloured leathers which tend to be thick and firm. This type of tannage is used to produce stout sole leather, belting leather and leathers for shoe linings, bags and cases.

- Aldehyde and oil tannages produce very soft leathers. This system can be used to produce leather that can be dry-cleaned and also washable fashion leathers and chamois leather. Aldehyde leathers meet the needs of the automotive industry.

Other chemicals that might be used in the tanning process of leather, are one or more of the following: Sodium sulfide, Sodium hydroxide, Sodium hydrosulfite, Arsenic sulfide, Calcium hydrosulfide, Dimethyl amine and Sodium sulphydrate. Biocides like pentachlorophenol might also be added to prevent bacterial growth.

3. Crusting

Crusting is when the skin is thinned, retanned and lubricated, culminating in the final sub processes of drying and softening. These are the main additional processes of making leather.

- Thick leather can be passed through a splitting machine, which slices thicker leather into two layers.

The layer without a grain surface can be turned into suede or it can have an artificial grain surface applied.

The layer without a grain surface can be turned into suede or it can have an artificial grain surface applied. - A uniform thickness can be achieved by shaving the leather on the non-grain side using a machine with helical (spiral shaped) blades mounted on a rotating cylinder.

- Neutralising removes any residual chemicals and prepares the leather for further processing and finishing.

- Additional tanning material may be applied to give particular properties which are required in the finished leather.

- The dyeing of leather into a wide variety of colours plays an important part in meeting fashion requirements. Some leathers are only surface dyed, while others like suede, need complete penetrated dyeing.

- Fatliquoring introduces oils to lubricate the fibers and keep the leather flexible and soft. Without these oils the leather will become hard and inflexible as it dries out.

- Samming is the process where the water content is reduced to about 55%. This is done by passing the hide through a number of machines, the commonest being like a large mangle with felt covered rollers.

- Through setting out, the leather is stretched out and the grain side is smoothed. This process further reduces the water content to about 40%.

- Leather is normally dried to have only 10-20% water content. This can be achieved in a number of ways and each method has a different effect on the finished leather. Staking and dry drumming: A staking machine massages the leather to separate the fibers. This makes the leather softer and more flexible. To finish off, the leather may be softened by tumbling it inside a rotating drum.

- Buffing and Brushing: Through mechanical rubbing, the flesh surface is removed to produce a suede effect or to reduce the thickness. In some cases the grain surface is buffed to produce a very fine nap, e.g. nubuck leathers. After buffing, the leather is brushed to remove excess dust.

- Finishing: The aims of finishing are to level the colour, cover grain defects, control the gloss and provide a protective surface with good resistance to water, chemical attack and abrasion.

- Surface coating is the last process if it is required.

The area of each piece of leather is measured by machine. Nearly all leather is sold by area so accurate measurement is important. Before the leather is dispatched to the customer, final grading will be done. This grading will control the colour intensity and uniformity, the feel of the leather, softness, visual appearance, thickness, design effects and natural defects such as scratches.

Reducing the Environmental Impact of Making Leather

Leather can be environmentally friendly if the hides are tanned naturally without using any chemicals. Eco leather is often regarded as an attempt to produce leather with as little environmental impact as possible. Organic leather comes from animals that are raised and slaughtered humanely. Tanning process of leather would use processes such as smoke and plant based tannins which are more environmentally friendly.

Environmentally friendly leather is defined by two basic parameters:

- How the leather is manufactured.

- The inputs used during the manufacturing process.

To make eco friendly leather, alternative manufacturing processes need to be included or followed to reduce the environmental impact. These are some of them:

- Use biodegradable wetting.

- Reduce the amount of sulfides processing.

- Introduce non-synthetic or polymeric re-tannage systems.

- Natural dyestuff need to be used or un-dyed or vegetable tanned leather.

- Use vegetable oil based fatliquors.

- Optimised the finishing systems to reduce waste.

- The leather need to be biodegradable in less than twelve months.

An eco friendly tannery needs to have its own wastewater treatment plant and must refrain from using certain toxic products, colours and finishes.

Where Does That Leave Us With Regard To What Is Eco Friendly Leather?

The leather manufacturing process is energy intensive (but so is synthetics that are petrochemical based) and often involves using processes that are harmful and destructive to the environment. Leather is often more profitable for farmers than selling the meat.

(but so is synthetics that are petrochemical based) and often involves using processes that are harmful and destructive to the environment. Leather is often more profitable for farmers than selling the meat.

At the end of the day all three tanning processes have a negative impact on the environment. With approximately 250 chemicals used in leather manufacturing, there is a huge negative footprint that is left by the process of making leather.

I do find that very scary!

Please look out for my post on vegan leather and this is where you will find it.

I look forward to hearing your comments. Please leave them below and I will get back to you.

Dear Sir/ Madam

We are wax products professional manufacturer in China which has many patents. We can provide low price and high quality wax products, such as PE wax, OPE wax, FT wax, OFT wax, maleic anhydride grafted wax, micronized wax, high class synthetic wax and PP wax.

1. Good hardness, wear resistance, anti-adhesion and stain resistance, improve the abrasion resistance, scratch resistance and enhance smooth feel;

2. Anti- adhesion, extinction effect is obvious, grinding and slippery, repainting, anti-sinking, good air permebility, improve the salt fog and moisture-proof effect, paint to improve the performance of paint remover, improve the leveling of baking enamel surface;

Thank you for reaching out. We do not manufacture any products, so I would suggest you contact manufacturers. All the best, Liné

Hi, your post is really helpful based on the research I am just learning the effect of tanning in our environment, which is not good at all, but leather is very useful to us, the problem is how can it be done without affecting us, I will be sharing your post in my social media so that others can benefit from your post, like me I don’t know that processing of leather is dangerous to our environment until I read your post.

Although the tanning process of leather has a harmful effect on the environment, the production of synthetic plastic leather is even worse. Real leather lasts a long time and will biodegrade, so I will choose real leather rather than synthetic vegan leather.

I am happy to hear that there is such a thing as vegan leather. I don’t really understand why people have made wearing leather into such a sort of fashion thing when it has all of these harmful effects on the environment.

I am sort of an environmentalist to so I appreciated reading this page. I will probably come back in the future and read some more eco-friendly articles. I will also make sure that people know about your page if I hear them talking about leather so they can learn about vegan leather.

Hopefully the cultural shift to wear more vegan leather will take place soon and anyone wearing animal leather will be sort of discouraged from doing so. It takes a while for the culture to catch up with stuff like this but I think eventually it does. So thanks for making your website and spreading the information.

Hi Charles, the tanning process of leather indeed has a big impact on the environment. Vegan leather is not the ideal either as most of it is made from synthetic materials, which means plastic, which is even more harmful to the environment than leather. We indeed do need a cultural shift to be chasing fashion and beauty less and concentrate on what is good for our bodies and our planet.

I come from an area where slaughtering of cows and goats is very common. I know very well the attack of insects on raw, fresh leather.

It is amazing to imagine that beautiful belts, shoes and handbags come from raw leather. The finished products are extremely beautiful from the raw product.

On the environmental factor, it is VERY Unfortunate that the process involves degrades the environment one way or the other. 250 chemicals is something to be scared of.

Thank you for taking your time to show us the processes.

The tanning process of leather unfortunately does harm the environment. More research is still needed into eco friendly leather and natural alternatives.

Gosh, that is very scary. Especially now that we know more about the damage we’ve inflicted on the environment.

I always assumed that vegetable-tanned leather is the best choice and obviously, compared to the traditional method, is infinitely better but from what you say, there’s not really much of a difference.

So, I guess the real question we need to ask is: What alternatives do we have if genuine leather and its alternatives have such severe consequences?

Thank you for highlighting something so important and widespread.

The tanning process of leather is indeed very damaging to the environment. Vegetable tanned leather is indeed the best choice out of the three, but is still not ideal when it comes to the environmental impact. I think our best choice would be natural vegan leather, not synthetic vegan leather, but that still has limitations.

As consumers we need to look at what and how much we buy and throw away.