The search for alternative cellulose fibers are leading to more innovative textile solutions. In this article we are looking at Nettles, Lotus and Mushroom Leather

Nettle Fabric

Fibers from the common stinging nettle plant have been used since ancient times to produce cloth. Nettle fiber production goes back to the roots of civilization and for more than 2000 years people have worn clothes made from stinging nettle fiber. When cotton arrived during the 16th century, nettle clothing lost their popularity because cotton is easier to harvest and spin. The German army briefly used nettle cloth for their uniforms during the second World War when there was a shortage of cotton.

Fibers from the common stinging nettle plant have been used since ancient times to produce cloth. Nettle fiber production goes back to the roots of civilization and for more than 2000 years people have worn clothes made from stinging nettle fiber. When cotton arrived during the 16th century, nettle clothing lost their popularity because cotton is easier to harvest and spin. The German army briefly used nettle cloth for their uniforms during the second World War when there was a shortage of cotton.

The 3 main sources for nettle fiber are European nettle, Himalayan nettle and Ramie.

- European nettle grows widely and easily

- Himalayan nettle is a large plant and grows mainly in the Himalayas, but also in Africa and other Asian countries.

- Ramie produces a fine fiber that is commercially produced in China and Japan

The fibers in all three of these species come from the stem of the plant and there is no sting left in the fiber. Nettle fibers are white and silky and up to 5cm long.

Giant Himalayan stinging nettles grow wild in many mountainous areas and new shoots grow more than 3 meters a year. The vertical dead stalks are harvested after a year, making space for the new shoots that can then absorb CO2. It also promotes root growth which contributes to soil stabilization in landslide prone mountains.

Ramie is also called Chinese nettle and is a perennial plant which grows like a shrub. Although it looks very similar to European nettle, it doesn’t have prickles. Ramie is one of the strongest natural fibers even when it is wet.

Ramie fiber is white and lustrous and looks like silk, but it has no stretch or elasticity, so when making knitting yarn it is blended with 30% wool to give it elasticity. It doesn’t shrink and is resistant to mildew and bacteria so it will not rot.

Making Nettle Fabric

The difficulty with nettle is to extract the fibers from the stems, which is a long and strenuous process. After cutting the nettles, the stalks are dried which removes the ‘sting’ from the stems. Once dried, the stalks are broken to remove the woody parts. The stems go through a process of water retting or dew retting to break down the cellulose outer layer and remove the sticky substances that surround the fiber bundles.

Root retting, leaving plants to die first, is often used for Himalayan nettles. Once the bundles have been dried, they are then broken, either by hand or by passing them through rollers and the fiber is extracted.

Nettle fibers are hollow, which creates natural insulation. Nettle fabric is very similar to linen, but stronger and a bit “stiffer” making it ideal for more structured garments.

The nettle plant grows almost uncontrollably, making it sustainable. It is naturally resistant to pests and diseases, (it is a weed after all!). Although the production of the fabric is labour-intensive as it is done by hand, it means no harmful chemicals are used and no pollution caused as is often the case with the production of other textiles.

New advances in spinning technology and cross-breeding, have produced high-fiber plants that are flexible, versatile, strong and has a good length of fiber for spinning.

Nettle cloth is expensive because of the intricate processing so is not widely used in the textile industry. Improvements in the processing methods will hopefully lead to this innovative textile solution being more widely used.

Lotus Flower Textile

The latest luxury textile is made from the lotus flower and is another innovative textile solution. Lotus flowers grow in water and are growing naturally in many lakes in Cambodia and the surrounding Southeast Asia. The Lotus flower is an ancient symbol of Buddhist culture symbolizing inner determination and spirituality.

The seeds and leaves of the lotus flower have for many years been harvested for use in medicines and also as a food source. In recent years the reedy stems and flowers are being cut, dried and woven into fabric that is luxuriously soft and silky.

Making Lotus Flower Fabric

To make lotus fabric is a laborious process and a single length of hand woven material requires about 6,500 lotus stems. The whole process, from harvesting to spinning and weaving, is done by hand using traditional Cambodian techniques. Stems are cut by hand and within 3 days they are then bunched, trimmed and sliced.

There are 20 to 30 threads inside each stem which are then pulled and hung to dry. Once the fiber is dry, it is spun into yarn and put onto bamboo bobbins. The yarn is then handwoven, taking 6 weeks to produce 90 meters of fabric. To produce 90 meters of fabric would require 32,000 stems.

The fabric is incredibly soft and light, naturally stain resistant and waterproof and the most ecological fabric containing no toxic products or chemicals. Lotus flowers are naturally waterproof and luxurious to touch. Fabric is organic and hand woven and an Eco alternative to cotton and silk.

The luxury cloth is very expensive, retailing at as much as $5,000 for a scarf, but as production and demand increases, this innovative textile solution will hopefully become more affordable to the general consumer

Mushroom Leather

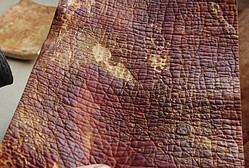

Replacing animal leather is possible and a vegetable alternative, called Muskin, has been developed from wild mushrooms. Muskin is completely made from the cap of Phellinus ellipsoideus, a gigantic, inedible mushroom species which is native to subtropical forests. These mushrooms feed on tree trunks, making them putrefy. By removing them from the trees it is also helping the trees.

Mushrooms are harvested by hand and dried for up to a year. It is then peeled and hand processed. Although it is an elaborate process, no chemicals are used during the processing, making it nature friendly.

Muskin looks very similar to animal leather, but it is a vegan product which is organic, gluten free and chemical free. It has a marble velvety surface with high absorbency and anti-bacterial and antiseptic properties.

Because the fibers are highly absorbent, it can be used as insoles to absorb moisture in shoes. It has successfully been used to improve athlete’s foot. It is non-toxic and doesn’t cause allergic reactions, so is ideal to be used for products that come into contact with the skin.

At the moment only 40 – 50 square meters of Muskin can be produced per month, making the leather suitable for use in limited edition collection. With all of us calling for a greener planet, this innovative textile solution will be explored more.

The world of luxury goods has been looking for more sustainable materials and processes. In March 2021, Hermés, the French brand that is synonymous with luxury, launched their first bag made from mushroom leather. The innovative materials is called “Sylvania” and the texture is similar to real leather.

Many luxury brands are trying to make their processes more sustainable, reducing waste, reducing carbon emissions and focusing on sustainable raw materials.

I hope you enjoyed discovering these innovative textiles and I look forward to hearing your comments and suggestions.

Thanks for writing this article. It is really informative.

I didn’t know plant leather existed. This is the first time that I am hearing about it. And you also mentioned its properties. It looks like a great option for shoes. And I like the mushroom leather shoe photo.

I am interested in mushroom leather shoes. I will search and find a pair for myself.

Hi there, there are some awesome textile innovations that are eco friendly and sustainable. Liné

Your article is indeed interesting. I love it when historical stories are made easy for one to read. And your site has done that for me. It is so beautiful that your article writes about where our clothing and shoes are made from.

You said To make lotus fabric is a laborious process and a single length of hand woven material requires about 6,500 lotus stems. Jesus, I can imagine how those people are working to achieve this. We really need to appreciate what we have, because we only see the end products and forget about the process. Thank you for this article

You are so right Augusta, more people need to be aware of the time and effort associated with producing certain fabrics and garments

I have really enjoy your article. I didn’t know that we can use the plants and mushrooms to make our everyday clothes. I see the world is a great place where we can help ourselves to achieve a lot of things without killing everything. My mind has opened to look for more things that will help us without killing our beautiful earth,

There are some very interesting fabrics being produced that will help our planet

After reading through your site, i didnt know this stuff exist. It looks like it takes a lot of time to grow, produce, amd manufacture. Than there’s great info on cost. I learned that it’s more expensive than i thought. Not sure but throughout our site you need links to other products or information that you woukd he directing towards a product in result is profits. After the first part of the site, I wasn’t fully engaged like first part. The second half is cool but doesn’t have that WOW I learned much

Hi Raul, It’s good to know that you have learnt from the article.

This is a great site showing how our natural resources and plants should be protected so they can be used for products like these. We tend to take all the things we have and wear for granted but should be grateful for different plants and and the useful properties of the plants. I like how the site goes into detail about how the structures of each plant are used. We should do more of this in our economy to further reduce our wastes. Well Done.

You are right Mark, we all need and can do more to recycle and look after the earth’s resources