Fabric dye and fabric dyeing techniques have a very high environmental impact. The use of harmful chemicals in fabric dye and the high amount of energy that is used and waste water that is produced, it leaves a big negative footprint.

With an increasing number of consumers looking for more sustainable and eco friendly fashion items, manufacturers and retailers are exploring alternative processes. We will first look at the traditional ways of dyeing fabric and then at the latest developments in new fabric dye.

Fabric Dyeing Techniques

Dyeing can be done at different stages during the production process of textiles. Depending on the stage where fabric dye is applied, different methods and techniques are used. The four stages are 1) Fiber, 2) Yarn, 3) Fabric or 4) Garment. Below are the dyeing techniques that are mostly used in the textile industry at the moment:

- Fiber stage – dyeing takes place before the fibers are spun.

- Solution dyeing – dyestuff is mixed in with the chemical solution if synthetic fibers are made or natural fibers are put in the dyebath. When the filament exits the spinarette, it is already coloured.

- Stock dyeing – the loose fibers are immersed in the dyebath before blending, combing, carding and spinning take place. This is the most expensive way of dyeing. But it produces a textile with excellent colour-fastness properties and uniform distribution of colour.

- Yarn stage – yarns that are spun are immersed in the dyebath before the fabric is woven or knitted. Interesting stripes, checks, tweeds and plaids can be created by using different coloured yarn when the fabric is woven. The dye penetrates all the way to the core of the fibers.

- Skein or hank dyeing – yarns are loosely arranged in skeins over a ring in a large container which is then submerged in the dyebath. It is suitable for yarns that cannot be compressed or stretched like wool.

- Package dyeing – during the spinning process, the yarn is wound on yarn carriers in packages. The packages could be cones, tubes etc. which are then packed in perforated frames. The dye solution is penetrated in a continuous movement through the packages.

- Beam dyeing of yarns – the warp threads are dyed before weaving. Warp threads are wound on perforated cylindrical beams which are placed in a machine. The dye is forced through the perforations, thereby saturating the yarn with colour.

- Fabric stage – colour is applied after the fabric has been created.

The fabric is immersed in the dyebath to get the desired colour. Most fabric is piece dyed and the most amount of piece dyeing is done on either beck equipment or jig equipment. Other piece dyeing methods include jet dyeing and pad dyeing.

The fabric is immersed in the dyebath to get the desired colour. Most fabric is piece dyed and the most amount of piece dyeing is done on either beck equipment or jig equipment. Other piece dyeing methods include jet dyeing and pad dyeing.

- Beck dyeing is a versatile and continuous process that is used to dye long meters of fabric.

Fabric is passed through the dyebath in rope form. The fabric rope moves over a rail onto a reel which immerses the fabric rope into the dyebath. It then draws the fabric up and forwards to the front of the machine. This process is repeated until the fabric has a uniform colour and has the intensity that is required. About nine hundred kilograms of fabric can be dyed at a time on beck equipment.

Fabric is passed through the dyebath in rope form. The fabric rope moves over a rail onto a reel which immerses the fabric rope into the dyebath. It then draws the fabric up and forwards to the front of the machine. This process is repeated until the fabric has a uniform colour and has the intensity that is required. About nine hundred kilograms of fabric can be dyed at a time on beck equipment. - Jig dyeing uses the same procedure as beck dyeing, but the fabric is at full width on rollers that passes it through the dyebath. Jig dyeing equipment can handle up to two hundred and fifty kilograms of fabric at a time.

- Jet dyeing – the fabric is placed in a heated column or tube. Jets of dye solution are forced through the fabric at high pressure. As the fabric is moved along the tube, the dye is continuously recirculated. Up to five hundred kilograms can be dyed at a time.

- Pad dyeing is like jig dyeing, in that the fabric is at full width during the dyeing process. The fabric is passed through a trough that contains the dye. It is then pressed between two rollers that forces the dye into the fabric and any excess dye is squeezed out.

- Beam dyeing of fabric – as with beam dyeing of yarn, the fabric is wound onto large perforated cylindrical beams. The dye is pushed through the beams to impart colour onto the fabric.

- Chain dyeing – This is used when yarns and cloth are low in tensile strength. Fabric ends are stitched together to form a continuous piece. This is immersed in the dyebath and run through in a continuous chain. This method affords high production.

- Beck dyeing is a versatile and continuous process that is used to dye long meters of fabric.

- Garment stage – after construction the complete garment is dyed.

- Paddle dyeing – garments are immersed in a large container in a paddle dyeing machine. Garments are loosely packed and a motor driven paddle circulates the dye solution in the container ,to impart colour into the garments. The technique can also be used to dye individual pieces before construction of a garment.

Special Dyeing Effects

Special effects can be achieved by using other fabric dyeing techniques like :

- Batik dyeing is one of the oldest forms of dyeing and originated in Java. Parts of the fabric is coated with wax so that the dye will only be taken up in the un-waxed areas. This can be repeated several times and with different colours to create a mottled or streaked effect.

- Burl or speck dyeing is done by hand and mostly on woolens by covering specks with special coloured links.

- Cross dyeing is used on fabric with mixed fiber content that have a different affinity for the dye. Thus, resulting in different shades in one dyebath.

Can Fabric Dye be Eco Friendly?

Yes, eco friendly fabric dyeing and finishing processes can be achieved. By using dyes that are free of chemicals and kind to the environment, dyeing can be eco friendly. Natural dyes derived from plants, fruit, algae, fungi, marine invertebrates (like starfish and sea urchins) and bacteria are all possibilities.

- Fiber-reactive dye is a dye that can react directly with the fabric. The dye bonds to the fibers due to a chemical reaction that takes place between the molecules of the fabric and the dye.

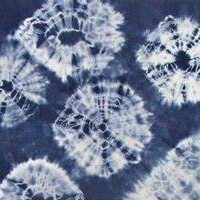

It is a permanent process effectively making the dye a part of the fabric. Fiber reactive dyes work best with cellulose plant fibers like cotton, linen, hemp, bamboo and viscose as well as silk. Mordants are not required to “fix” the colour when using fiber-reactive dyes. Fiber-reactive dyes also use less water, salt and heavy metals than normal fabric dyes. Because the colour is permanent, articles can withstand many washes and still retain its original colour. It is commonly used for tie-dyeing.

It is a permanent process effectively making the dye a part of the fabric. Fiber reactive dyes work best with cellulose plant fibers like cotton, linen, hemp, bamboo and viscose as well as silk. Mordants are not required to “fix” the colour when using fiber-reactive dyes. Fiber-reactive dyes also use less water, salt and heavy metals than normal fabric dyes. Because the colour is permanent, articles can withstand many washes and still retain its original colour. It is commonly used for tie-dyeing. - Bio-degradable dyes do not require the use of heavy metals, amines and inorganic salts. So they will decompose easily, without leaving any landfill in the environment. Fiber-reactive and bio-degradable dyes and pigments can be used to reduce the consumption of water and reduce environmental pollution.

- Azo-free dyes are free of nitrogen based compounds that release aromatic amines. Azo dyes are organic compounds that contain heavy metals. These contain toxic and carcinogenic substances, so dyes that are free of heavy metals, are used to produce eco friendly and sustainable textiles.

- Herbal dyes, that are bio-degradable and have medicinal properties, have also been developed. It can be used to make textiles with anti-inflammatory, anti-bacterial and anti-allergic properties.

Indigood Dyeing Technique

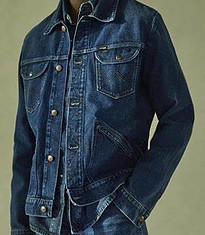

In June 2019 the fashion label Wrangler, integrated a new eco-friendly dyeing process, called Indigood, into its various production sites. Indigood is a revolutionary new process that uses a foam to create the indigo colour that is used to dye denim. It is a sustainable new way to transfer dye onto yarn and fabric.

into its various production sites. Indigood is a revolutionary new process that uses a foam to create the indigo colour that is used to dye denim. It is a sustainable new way to transfer dye onto yarn and fabric.

The process eliminates water from the dyeing process, so there is basically no waste water, while there is nearly a hundred percent water saving. Energy consumption and other waste is also reduced by more than sixty percent, which should allow the fashion group to save 5.5 billion liters of water by 2024. The result is a more sustainable pair of jeans or denim garment.

Indigood is set to revolutionize the fashion industry. You can read about brands like Levi’s and Patagonia that are using eco friendly techniques in this post on 8 Best Green Jeans Denim Brands.

Fabric Dyeing Techniques that are Eco Friendly

Cold dyeing, dry heat fixation, and vegetable tanning or chrome free tanning are some processes that textile manufacturers and dyeing houses use to develop eco-friendly garments and fabrics.

- Bleaching is done to remove any natural colour and impurities from the fiber and to increase the whiteness. Eco-bleaching is a process where non-chlorine substances, like hydrogen peroxide, are used to whiten fabrics without releasing any harmful chemicals in the process. Hydrogen peroxide breaks down naturally when it comes in contact with oxygen and water and turns the fabric white.

- Silicates and natural phosphates are used in a popular green bleaching procedure. When silicates and natural phosphates are used together with cow dung, and exposed to sun, it bleaches the natural fabrics.

- Low temperature bleaching is a process which uses peroxide activators to control its decomposition and simultaneously start developing the required whiteness. No methane gas is involved in this method and the emission of carbon dioxide is reduced by up to 50 percent.

- Dyeing fabrics with a special enzyme solution reduces the requirement for singeing. Washing especially knitted fabrics with enzymes can also help to remove any excess dye. These processes can save seventy thousand liters of water and thousands of kilos of carbon dioxide emissions for every ton of knitted fabric that is made. Using enzymes, rather than chemical additives, reduce carbon dioxide emissions and ultimately reduces energy consumption.

- Ink-jet printing is a process whereby the fabric dye is applied directly to the fabric. This printing process does not make use of large amounts of water and has low power consumption.

Several textile and garment manufacturers are treating waste water. The dye bath water can be reused and thereby helping to save tons of water, without fixing the colour of one bath to another one’s fabric.

So What makes a Low impact Fabric Dye?

Low impact dyes look at the type of dye and the dyeing process. OekoTex Standard 100 classifies eco friendly dyes as dyes that do not contain toxic chemicals or mordants, require less rinsing and have an absorption rate in the fabric of at least seventy percent.

The traditional dyeing process involves washing, bleaching and preparing the fibers or fabric ready for dyeing and then rinsing and cleaning after the dye bath. Most dyes need to be dissolved in hot water and then kept at a high heat for the dye to be absorbed by the fiber, so more energy is used. The dye bath uses heat, chemicals, time and agitation.

Chemicals are used to prepare the fibers and fix the colour permanently. For instance salt is needed for reactive dyes to attract them to cotton and then an alkali as a mordant to fix the colour. Leveling and wetting agents are also required during the dyeing process,

A low impact dye looks at these:

- Toxicity of the dye – if dye causes an allergic reaction or contains toxins or carcinogens, then it will not be low impact.

- Water and energy usage – low impact dyes use less water and lower temperatures.

- No auxiliary chemical loading.

- Absorption rate of the dye – in many dyes only fifty to seventy percent of the dye reacts with the fibers with the rest of the dye ending up as waste in water. Low impact dyes have a high absorption with eighty to ninety percent staying on the fibers, so far less waste.

Conclusion: by using bio-degradable substances and adopting fabric dyeing techniques that are eco friendly, chemicals in landfill can be reduced and it can save natural resources like water and energy.

Related post: What is Fabric Dye?

If you have any questions or comments about fabric dye, then please leave them below and I will get back to you.

Hi Liné,

I’m curious if you may have a resource for eco-friendly dyed fabric available for wholesale or retail sale? I hand dye linen fabrics with natural plant & earth pigments for my textile art but looking for a more water friendly pre-dyed option.

Thank you!

Your hand dyed linen fabrics sound amazing. Unfortunately I do not have a resource for dyed fabric that is also eco-friendly, but as soon as I find one, I will let you know.

I am so glad that more and more the world is turning to or inventing ECO products and procedures. I have no experience with the topic but I am happy to hear that there are eco fabric dyes, or at least we are getting there to help to heal our mother Nature.

Thanks for the article!

Hi there, most dyes are chemically derived, which is harmful to the environment and aquatic life. The dyeing process also uses a huge amount of water, which is not sustainable.

More brands are implementing eco friendly dyes and dyeing techniques, which is always good to see.

I had no idea just how many dyeing methods there were. It is nice to see that there are ways of using eco-friendly versions. I am a big proponent of going as natural as possible. I think it is so much healthier for both the individual and the environment as a whole. I think it is cool to see such a major company in Wrangler taking steps to help. Do you know if other companies have started to follow suit?

Hi Steve, yes there are other brands and companies that are using dyeing techniques now that are better for the environment and people. Levi and Patagonia are two of them and also other denim brands. You can read more about them in this post about the 8 Best Green Jeans Denim Brands.

I hope this will help you. Liné

Where I leave, in Africa, we use toxic fabric dyeing a lot, at a point we don’t even consider it as a threat to environmental safety. I guess it might take some time and effort to change people’s mindset about it, although there are some who have always been eco friendly: those that create Bogolan, a traditional fabric made in Africa, dyed with leaves and mud. You just made me a fan of Wrangler even if I’m not that fan of denim. By delivering such valuable content, you’re contributing to the fight for our environmental protection, thank you for that.

Hi Ibrahim, Bogolan sounds like a fascinating way of dyeing with leaves and mud. I will definitely have a closer look at how this traditional fabric is made, so thanks for that, Liné

Interesting article about eco-friendly dyeing. In the past, no company was concerned about the planet and now so many are getting involved with ecofriendly. In your article, you listed the difference in eco dyeing one of them being Bio-degradable dye, this one to me should be used more. Eco friendly is important in my view. Thanks for putting this article together about eco-friendly dyeing.

Hi Jannette, Hopefully with more consumers asking for eco friendly and sustainable products, more companies will switch to using eco processes, and dyeing would be one of them. Liné

A friend of mine does dyeing. I don’t know what process she uses though because apparently, there are so many different ways for one to do that. I think that ecofriendly dying is the best and it can help with conserving the chemicals like you have said. Using nongradable substance will be a better option but is it cheaper to use them because I want to share this with my friend.

You are welcome to share the post John. One can also make dye from food and plants like berries, turmeric and tomatoes that are natural.

Not in my wildest dream could I ever think that fabric dying could ever be eco friendly. It was even among the reasons I decided against pursuing a career in it. I learnt it but I realised that it is detrimental to nature because of the harsh chemicals use. Thanks so much for this post and I really wish that most people get to see this and reduce the level ay which they make use of dyes that are chemical filled. I’d surely share this out and besides, the techniques you shared too could come in handy to most people. Thanks

Developments like Indigood which doesn’t use water for the dyeing proces, is certainly very good news. Hopefully more fashion houses will take up the initiative as well.

Really interesting and in-depth article. I often dye my clothes at home and the last few times I’ve done it I’ve wondered about its environmental impact and whether I should really still be doing it. Obviously the problem is a lot bigger than just home dyers like me, this is something that the textile and clothing industries really need to start thinking about. It’s good to know that there are alternatives to the synthetic dyes, and also, that there is an alternative that needs no water. I really hope the industry gets behind these sorts of initiatives and makes changes to its practices soon.

I think the issue is with the textile industry, rather than you dyeing fabric or clothes at home. Fabric dye can be made from natural and plant substances that is better for the environment.