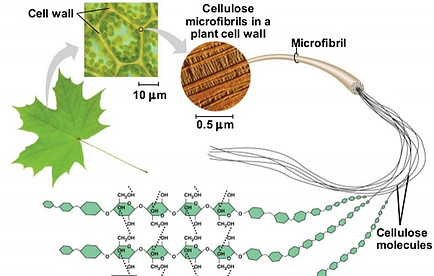

Viscose fabric is made from cellulosic fibers which might make you wonder, what is a cellulose fiber?

To get a better understanding of what is a cellulose fiber, we will look at what cellulosic fibers are used for and how is viscose made. We will also explore the types of natural cellulosic fibers and man-made cellulose fibers like viscose and rayon, as well as the difference between rayon and viscose.

So what is a Cellulose Fiber?

Cellulose or cellulosic fibers are structured from a starch-like carbohydrate, called cellulose. Cellulose is a fibrous material of plant origin which can be obtained from bark, wood, the leaves of plants or other plant based materials.

The main application of cellulosic fibers are in the textile industry, but they are also used as chemical filters, fiber reinforcement composites and in the medical field.

Categories of Cellulosic Fibers

There are two main categories of cellulosic fibers – those that are processed using only natural materials and those that are man-made, chemically produced.

- Natural cellulosic fibers – include linen, cotton, hemp, sisal and ramie (more about them below)

- Man-made cellulose fibers – viscose and rayon are the main man-made cellulose fibers (more about them below). The cellulose comes from plants that are processed into pulp. It is created by dissolving natural materials, such as wood pulp and cellulose and then regenerated by extrusion and precipitation. The fibers are extruded in the same way that synthetic fibers like nylon and polyester are made, but the cellulosic fibers are produced by regenerating dissolved forms of cellulose.

There is a very fine line or distinction between man-made fibers that are derived from natural sources (like viscose and rayon) and actual synthetic man-made fibers (like nylon and polyester).

1. Classification of Natural Cellulosic Fibers

Plant or vegetable fibers are classified according to their source within plants. So natural cellulosic fibers can be divided into these three groups according to the origin in the plant.

- Seed Fibers. Seed fibers are the most important plant fiber and is the source of cotton.

There are more than 250,00 species of plants that produce seed or hair fibers, but less than one percent are used for commercial purposes and these are the main ones.

There are more than 250,00 species of plants that produce seed or hair fibers, but less than one percent are used for commercial purposes and these are the main ones.

- Cotton: Cotton is the most commonly used natural cellulose fiber. The fibers grow from the seeds in the seedpod and each seedpod contains seven or eight seeds. Each seed could have up to 20,000 fibers growing from it.

- Coir: is a stiff fiber that comes from the husks of coconuts. The fibrous mass sits between the outer shell and husk of the coconuts. It is normally used to make highly durable indoor and outdoor mats, rugs, ropes and tiles.

- Kapok: Kapok fiber is soft, lightweight and hollow and comes from the seed of the Indian or Java kapok tree. As the fiber breaks down easily, it makes it difficult to spin into yarns. It is used as stuffing in pillows and fiberfill in other bedding products. Kapok is very buoyant and used to be used as a stuffing for life jackets and the mattresses on cruise ships.

- Milkweed: the properties of milkweed are very similar to those of kapok.

- Bast or Stem Fibers: Bast or stem fibers form the fibrous bundles in the inner bark or bast of the stems of the plant. These are soft fibers that are suitable for use in textiles.

- Flax: Flax is one of the oldest textile fibers and linen fabric is made from the flax fiber.

- Bamboo: Bamboo fibers come from the stem of the bamboo plant. Plants require very little water and no insecticides or pesticides are needed during the cultivation. This makes bamboo a sustainable and eco friendly fiber.

- Hemp: Hemp is very similar to flax and the fibers range in length from ninety centimeters to over four meters (three to fifteen feet). The growing of hemp has a low environmental impact as it does not require pesticides. It produces 250% more fiber than cotton and 600% more fiber than flax on the same amount of land. Hemp plants can be used to extract pollutants like zinc and mercury from the soil. Hemp fibers are used to make clothing, ropes, household linens and paper, while the seeds have medicinal and culinary uses.

- Ramie: Ramie fibers are whiter and softer than flax and are ten to fifteen centimeters (four to 6 six inches) long. Although ramie is strong for a natural fiber, it lacks elasticity, resiliency and elongation potential. It does not retain colour and dyes well, unless it is dry-cleaned. It is resistant to mildew, insects and shrinkage. Ramie is used for clothing, table and bed linens, paper, ropes and window treatments.

- Jute: Jute is one of the cheapest textile fibers, but also one of the weakest cellulosic fibers. Jute has poor elongation and elasticity, it has low resistance to sunlight and mildew and is not colourfast. It is used to produce bags for sugar and coffee, carpet backing, wall coverings and rope. Burlap is made from jute.

- Leaf Fibers: Leaf fibers run lengthwise through the leaves of monocotyledonous plants (plants that have a single or mono embryonic leaf) and are also referred to as hard fibers.

- Pineapple (Pina): Piña fibers come from the leaves of the pineapple plant. It is used to make lightweight and sheer fabrics for clothing and table linens and it is also used to make mats.

- Abaca: Abaca fibers come from a species of the banana tree family. The fibers are coarse and very long, up to four and a half meters (fifteen feet) long. The fibers are strong, durable and flexible and it is used to produce clothing, table linens, ropes, floor mats and wicker furniture.

- Pineapple (Pina): Piña fibers come from the leaves of the pineapple plant. It is used to make lightweight and sheer fabrics for clothing and table linens and it is also used to make mats.

2. Man-made Cellulosic Fibers

The main source of man-made cellulosic fibers is wood pulp, which usually comes from pine, spruce, or hemlock trees and also cotton linters. Cotton linters are the fine, silky, curly fibers that adhere to the cotton seeds after ginning and is used for cellulose.

Viscose fabric and rayon fabric are both manufactured from cellulose fibers that come from wood pulp. Viscose and rayon are produced in a number of ways, but regardless of the manufacturing process, the basic raw material is cellulose.

Allbirds produce sustainable footwear and apparel using eucalyptus tree cellulose fibers, for their eco friendly products.

Viscose was the first man-made fiber that was developed and was first produced in the late nineteenth century. It was originally called artificial silk as it was discovered when the silk industry was being threatened by a disease among silkworms. The name rayon was then given to it in 1924.

Vitamin A produce made swimwear and leisure wear clothing using sustainably made viscose, recycled nylon and natural fibers.

Nudie Jeans is an environmentally conscious Swedish fashion brand that use organic cotton to produce sustainable denim jeans. They also use lyocell viscose in their garments.

The difference between Rayon and Viscose

There is not a substantial difference between rayon and viscose and the two terms are often used interchangeably. Viscose is a type of rayon which is made from viscose, but it is also an alternative name for rayon.  It is the terminology which makes it all very confusing.

It is the terminology which makes it all very confusing.

The term viscose comes from the word viscous, which is the liquid state of the spinning solution. The viscose process is the most common way in which rayon is produced these days.

Viscose is a viscous orange-brown solution which is obtained by dissolving cellulose in sodium hydroxide and carbon disulfide. It can be converted back to cellulose by an acid, as in the manufacture of cellophane.

Viscose is the term that is used internationally, with rayon being used in the USA. So at the end of the day, viscose fabric and rayon fabric is basically the same thing.

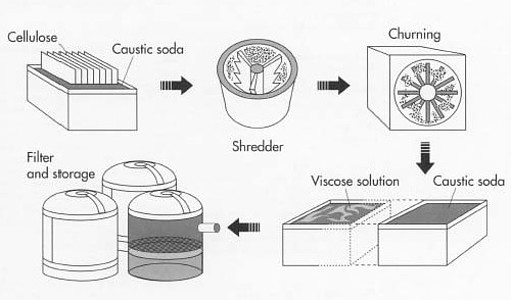

How is Viscose Made?

Viscose fabric is produced from plant cellulose which undergoes several chemical processes. Viscose is made from regenerated and purified cellulose which is primarily derived from wood pulp. It is made by mechanically pulping the plant cellulose and then chemically liquifying the pulp with toxic chemicals. These are the main processes involved:

- Cellulose extraction is done by mechanically pulping the plant cellulose to have a wood pulp with a minimum or ninety percent cellulose.

- Alkali cellulose conversion: purified sheets of cellulose are steeped in sodium hydroxide (also called caustic soda). This produces a chemical reaction that converts the cellulose into an alkali cellulose. It also removes impurities from the cellulose.

- Pressing: excess liquid is removed from the alkali cellulose by pressing it between two rollers. The pressed sheets are shredded into crumbs to form a substance called “white crumb“.

- Aging: the white crumbs are then aged though exposure to pure oxygen. This takes place in metal containers over a period of two to three days, with the temperature and humidity carefully controlled.

- Xanthation: After the aging process, the crumbs are combined and churned with liquid carbon disulfide. This turns the crumbs into an orange coloured mixture called sodium cellulose xanthate (or yellow crumb).

- Ripening: The cellulose xanthate is again steeped in sodium hydroxide (caustic soda), resulting in a viscous solution that feels and looks very much like honey.

- Filtering: the solution is filtered and any gas bubbles are removed.

- Extruding: Filaments are then produced by forcing the spinning solution through spinnerets.

- Acid bath: the resulting substance is immersed in sulfuric acid to get viscose filaments.

- Spinning – the viscose filaments are spun and can be woven or knitted to produce viscose fabric.

So through chemical means, the cellulosic fibers are converted into a soluble compound. The filaments are then chemically solidified and the resulting fibers are nearly pure cellulose. So viscose is a man-made fiber from natural materials and is often known as regenerated cellulose.

Most bamboo fabric is made using the viscose method, which is why you often see labels with bamboo viscose or bamboo rayon on it.

Properties of Viscose Fabric

- Viscose fabric can be produced at a relatively low cost and is commonly

used as a substitute for cotton because it is often cheaper to produce.

used as a substitute for cotton because it is often cheaper to produce. - It is breathable and highly absorbent, making it comfortable to wear.

- Viscose fabric drapes well because of the lightness.

- It is easy to dye and retains colour well.

- Viscose can be blended with other cellulosic fibers or synthetic fibers to make different textiles.

Some of the disadvantages are that viscose doesn’t age well, with yellowing of the fabric and pilling in areas of heavy wearing. Viscose is not as strong as natural cotton or flax, specially when it is wet, so gentle washing is required.

Other types of viscose fabric or rayon are modal and lyocell.

Environmental Impact of making Viscose Fabric

Although viscose is made from cellulose which is a natural substance, it doesn’t consist of cellulosic fibers only. Several toxic chemicals, including sodium hydroxide and carbon disulfide are used in the manufacturing process. It is the production process of viscose that has a big impact on the environment.

The toxic chemicals that are used in the production of viscose, pollute the waterways and reduce the air quality. About seventy percent of a tree is wasted when the wood pulp is extracted. Ecosystems are damaged through water pollution and forests are depleted at a rapid rate.

So although cellulose is an eco friendly substance, the manufacturing of viscose fabric is not sustainable.

I hope this has explained what is a cellulose fiber and the difference between rayon and viscose, but if you have any questions or comments, please leave them below and I will get back to you.

This was a really informative read about viscose fabric. I’m glad to have more knowledge about the material in order to make more informed choices about the purchases I make. It’s too bad that there are toxic chemicals that go into the production of viscose, because the material can be beautiful. We must consider the long term impacts of our choices.

I fully agree with you that we must consider the long term impact of our choices and consider the environment as well as our health.

Nice Article ??? ??

Thank you

I had no idea that producing a man-made fiber was so extensive as well as having such a negative effect on the environment. It sounds as if we’d all be better off if we stuck to linen ad cotton clothing. I happen to believe that natural fibers feel better against the skin. The question I have is if sticking to natural fibers in the clothing industry is feasible.

Hi Sherman, I agree with you that natural fibers feel much better against the skin than synthetic fibers, and specially textiles like organic cotton, linen, hemp and bamboo. I think it is feasible to stick to natural fibers for clothing and progress is being made to use more eco friendly production processes.

Hi, Line, I like your post. I was just wondering if can get cellulose from natural products, why do we need to make Viscose through a chemical process? You would think this could be done through a more sustainable process, or am I wrong about this? Line can maybe elaborate abit more on this?

Hi Eric, it is the conversion of the cellulose into viscose fabric that goes through a chemical process. Increasingly the lyocell process is used to make viscose fabric. This process uses N-Methlymorpholine N-oxide as the solvent, which produces very little waste and is more eco-friendly.

Hello there, thanks for sharing such educational post. I haven’t heard much about the making process involved in getting viscose from cellulose before and reading its process here is a really wonderful thing. I love the detailed explanation and how it can be gotten artificially and its natural form. Although it looks pretty new to me, I look forward to learning more about it. Thanks for your time.

Hi Chloe, viscose fabric is made from cellulose, which is a natural fiber, but the process of making viscose fabric involves chemicals. So viscose fabric is man-made, but using cellulosic fibers which are derived from wood pulp and other plant materials.

This is a very educative one here. I didn’t understand before about cellulose products and viscose fabric. I really like how you have explained it. It’s sad though that a fabric that is made from natural sources can be a harm to nature, trees and humans generally. I guess there should be other ways of making very good fabrics that is ecofriendly because even with using chemicals, it still isn’t durable. Thank you for the eye opener.

Hi John, yes indeed it is the production processes that use toxic chemicals that are harmful to the environment.

Increasingly the lyocell process is used to make viscose fabric. This process uses N-Methlymorpholine N-oxide as the solvent, which is more eco-friendly as it produces very little waste.

This is a good topic for environmental investigatory project. In the school where I work, the whole academic community are reminded to use eco friendly materials that’s why plastic is banned. This topic is interesting because it’s not common for everyone to know that not all eco friendly material is sustainable. The production and manufacturing process should also be known before identifying the product if its safe for the environment.

Our country is specializing in piña and abaca because it’s widely abundant all over the regions. Local government is urging people to support these products. I hope there are more community or nationwide programs that oversee the sustainability of eco friendly materials. I am glad you have profoundly discussed this matter with comparison and examples to better understand how to identify a product.

What a great initiative that your school has banned plastic use! Pina and abaca are both beautiful fabrics and although it is still more expensive to produce than some other natural textiles, through your local government promoting it’s use, production will increase. We need more governments to support local products and sustainable manufacturing methods.

Thank you for the informative article. I did not realize that viscose and rayon referred to essentially the same thing. A lot of my clothing actually is made of rayon but I honestly had no idea where it came from or how it was made.

Although I do prefer more natural fabrics, my budget does not. Although the rayon does not wear as well or for as long, I find that it generally suits my needs. In all honestly, I don’t want to own a piece of clothing forever !

At the end of the day there is note really a difference between rayon and viscose, it is the terminology that is confusing. Viscose fabric is made from cellulose and so is rayon.