Eco friendly floors make an attractive addition to a “green” home and bamboo flooring is one of the options. Bamboo is a sustainable renewable flooring alternative that is eco friendly, durable and affordable. It is one of the toughest natural materials, but still flexible. Here we will be looking at how bamboo flooring is made and the options available. We will also look at bamboo flooring: the pros and cons. This is where you can read about other bamboo fiber products.

What is Bamboo?

Bamboo is a perennial evergreen plant and there are approximately a thousand different species. It grows primarily in southern and eastern Asia, but also in many other tropical and sub-tropical areas. Bamboo needs no pesticides or herbicides to flourish and can grow in poor soil as well.  Many bamboo varieties can grow as much as a meter a day and has a diameter of around 32 centimeters (13 inches).

Many bamboo varieties can grow as much as a meter a day and has a diameter of around 32 centimeters (13 inches).

Bamboo flooring is made from the largest bamboo variety called Moso bamboo, which is not actually eaten by pandas. Although it looks like hardwood flooring, bamboo flooring is a natural material which is made from the fastest growing plant, grass.

When the bamboo is cut, the roots are left intact in the ground, making it completely self generating. Only the best quality bamboo stems, called culms, are used for bamboo flooring. Each stalk is cut from the middle part of the culm.

It will be easier to understand how grass is transformed into a durable flooring option, if we look at how bamboo flooring is made.

How Bamboo Flooring Is Made

Traditionally the method of making bamboo floors involves slicing the stems of the plant into thin, flat planks. Depending on the desired effect, these can be left untreated or stained or varnished a particular color. These strips are then nailed down to wooden beams or larger bamboo pieces to create a support system.

Depending on the desired effect, these can be left untreated or stained or varnished a particular color. These strips are then nailed down to wooden beams or larger bamboo pieces to create a support system.

Generally, the planks are arranged loosely, leaving irregular gaps throughout the floor. The resulting floor can breathe and it creates a room that stays cooler and more ventilated in the summer. This is the most common type of bamboo flooring used in Asia and it is also commonly found in homes built on stilts.

The modern process of making bamboo flooring involves several steps:

- Harvesting is the first step in turning bamboo stalks into flooring. Bamboo is normally harvested after the summer, but before the rainy season, as the moisture level within the plant is then low. The sugar content must also be low when the bamboo is harvested to reduce the risk of termites and insects attacking the bamboo. Bamboo is normally cut by hand and the bamboo roots stay alive that the plant will regrow. Harvesting normally takes place every 4 to 6 years.

- Splicing, sorting and milling – the green outer hull is removed by peeling it away. The stalks are split into strips and the hollow bamboo poles are fed through a specially designed slicer, splicing the poles into thin, equally sized strips. The stalks are cut into strips lengthwise and the strips are milled flat. Excess trim is used for making strand woven bamboo. After splicing, the joints and nodes between the sections are sanded down to create a smooth surface.

- Boiling is the next process – strips are boiled to remove any grime and insects and it removes any starches and sugars from the bamboo strips. This prevents decay and the bamboo will have less appeal for termites and pests. The final product will be less susceptible to contraction and extraction due to humidity and changes in moisture levels, thus making it very good for countries and areas with high levels of humidity.

- Carbonisation is sometimes done as an optional process. The natural color of bamboo is a soft, light tan color; but it can be darkened by using a process known as carbonisation. The bamboo is steamed using a controlled blast of pressure and heat. This causes the surface of the bamboo to take on a darker and richer hue. Unfortunately, carbonisation can also reduce the hardness and durability of the bamboo.

- Kiln drying – quality inspection is first done and whether it is carbonized or not, the bamboo slices are then kiln dried to remove moisture.

- Manufacturing – the dried strips are glued together into one of three styles: (more details about each further in the post)

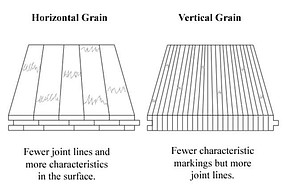

- Horizontal Bamboo Flooring – glueing the wider surfaces together, face up, and laminated for uniform thickness. Natural nodes and knots in the bamboo are displayed randomly.

- Vertical Bamboo Flooring – the narrow edges of several strips of bamboo are glued together with a thin layer of lamination to give a uniform smooth appearance.

- Strand woven Bamboo Flooring – fiber remnants are intricately woven and compressed, together with an eco friendly safe resin. It forms incredibly strong boards that are scratch and UV resistant.

- Milling – All three manufacturing processes will go through the final stages where the boards are milled again to refine them. As with most wooden flooring, bamboo flooring use a tongue and groove system. The planks are milled with tongue and groove to ensure a snug fit during installation. A new click system has also been developed whereby the planks just click together without the need for additives.

- Sealing and finishing process – a clear coating like aluminium oxide is applied to give more protection against damage and wear and tear. Often a moisture seal and UV protection would also be applied.

- Quality control and packaging – the bamboo flooring is inspected for quality before it is boxed and shipped.

Manufacturing Stage of How Bamboo Flooring is Made

Solid Bamboo Flooring

Solid Bamboo Flooring involves a complex manufacturing process. The first step is to slice the stalks of the plant into thin strips of a certain length. The outer green layer is removed and the strips are boiled in boric acid to remove any starches that may be present. The material is then laid out to dry. The strips of bamboo are then coated with an adhesive resin and are laid horizontally or vertically and then pressed together. The overall look will be different, depending on which method is used. If laid horizontally, the flat strips are laying on top of one another, or if laid vertically, the strips are stood on end and pressed together from either side.

The strips of bamboo are then coated with an adhesive resin and are laid horizontally or vertically and then pressed together. The overall look will be different, depending on which method is used. If laid horizontally, the flat strips are laying on top of one another, or if laid vertically, the strips are stood on end and pressed together from either side.

Either way, a solid and durable plank is formed by pressing the individual strips together.

To dry the adhesive and join any disparate strands, the bonded strands are then heat pressed. The raw material is then planed and sanded down into the final planks that will be used as flooring material. To assist in the curing process, a light UV lacquer is then applied to the planks. Finally, the planks are sanded to a smooth finish, and any desired finish is applied.

Strand Woven Bamboo Flooring

With Strand Woven Bamboo flooring ,  during the milling stage of production, remaining strands are trimmed from the long bamboo fillets. Strand woven bamboo flooring is made from a by-product that might have been wasted otherwise.

during the milling stage of production, remaining strands are trimmed from the long bamboo fillets. Strand woven bamboo flooring is made from a by-product that might have been wasted otherwise.

The thin strands are woven together and mixed with resin and compressed. It is often boiled, but it can be dipped in borax. Using heat and pressure, the fibers are then pressed together into blocks. The blocks are then cut into usable plank sizes, sanded and any stain or finish is then applied.

So to briefly summarize how bamboo flooring is made: bamboo stalks are cut into flat strips that are milled and then boiled, sometimes carbonized, kiln dried and glued together into floorboards.

Engineered Bamboo Flooring

Engineered Bamboo Flooring consists of a relatively thin surface layer of bamboo, bonded to a wood or high-density fiberboard (HDF) substrate layer.

As is done for solid bamboo flooring, the stalks are still sliced, treated and adhered together. However, after this is complete, the solid planks are then sliced down into thin horizontal layers. These thin slices are then glued onto a backing material such as plywood or fiberboard using heat and pressure.

Unfortunately, an urea-formaldehyde adhesive is used in the process of glueing the bamboo fibers or strips together. This emits volatile organic compounds, known as VOCs, which can be harmful to the air quality in an interior space.

Different manufacturers use different amounts of adhesive and its toxic effects will vary depending on the manufacturer of the material. In some cases, the VOCs emitted will be less than those found in manufactured carpeting.

It is therefore very important that you make sure that your bamboo flooring was produced according to the highest environmental standards.

Bamboo flooring: the pros and cons

- Environmentally friendly: no harmful or toxic chemicals or pesticides are used to grow bamboo.

- Sustainable resource: The bamboo plant is a renewable resource and it matures in as little as five years. Hardwood trees normally take from twenty years to a hundred and twenty to reach maturity, so bamboo takes much less time and naturally regenerates itself as each harvest.

- Low maintenance: Bamboo flooring is relatively easy to maintain. Regular sweeping or vacuuming to remove dust and debris is required. When it is required, you can also mop it or clean it with a non-alkaline and non-wax bamboo or hardwood floor cleanser, but avoid stem cleaning and excessive use of liquids.

- Water resistant: Bamboo is slightly more resistant to stains, water damage and warping than hardwood materials, although it is still a concern and is therefore not suitable for use in bathrooms and basement areas where the humidity level might be too high.

- Natural material: As people are becoming more ecologically conscious they are demanding products that reflect these values. The use of natural materials is an important trend in the construction industry

- Affordability: Bamboo flooring is priced at about the same level as most hardwood floors, from about $2 to $8 per square foot. You should avoid bargain-basement materials as they are often lower quality castoffs.

- Durability: There are certain types of bamboo that can be extremely strong, hard, and durable. Natural uncarbonized bamboo that was properly harvested and manufactured can be as durable as red oak. Darker options are carbonized and not as hard. Strand woven bamboo flooring is even harder than solid bamboo flooring.

- Style: Bamboo is a trendy flooring material that can elevate the elegance of a space almost instantly. Bamboo flooring has horizontal lines with a soft golden natural color. The appearance and feel is similar to that of hardwood, but yet it is distinct and different.

- Refinishing: Bamboo floors may become discolored or scratched over time. Fortunately the surface of this material can be refinished, sanding it down and then reapplying the finishing coats to give it a fresh new look. The thickness of the planks will determine the amount of times that refinishing that can be done.

- Recyclable: bamboo flooring can be recycled or upcycled when it reaches the end of its life

The benefits of bamboo flooring far outweigh the disadvantages. Almost the only negative aspect of bamboo flooring is that pollution might be caused in transportation as bamboo is mostly produced in the Pacific Rim.

Some Final Thoughts On How Bamboo Flooring Is Made

While the best quality of bamboo flooring is made using eco friendly materials and practices, some companies want to produce a product that is cheaper. They use premature bamboo (that is less than four years old) and high levels of additives, like formaldehyde, during the glueing process. This has a negative impact on the environment and also affects the quality of the final product.

Always make sure that you are using a reliable source and check on emissions before buying. Bamboo flooring should have a smooth and uniform texture without any gaps or fillers. This is where you can get the best prices and options for bamboo flooring products.

Please leave your comments and questions below and I will get back to you.

oh Bamboo flooring is so beautiful. Truly I love it. I like the traditional method the most, I think it will suit my wood home perfectly. I think it’s time for a change, bamboo flooring is the way to go. Maybe I should pull all my floors out and just put new Bamboo flooring everywhere…. I’ll probably give someone a heart attack. This is definitely in the plans on my next renovation. Thank you for a great post with wonderful information. Great success to you

Hi Marlene, bamboo flooring is beautiful and easy to clean and maintain, while also being sustainable and environmentally friendly. I am sure you will benefit from including it in your next renovation. Liné

I did not know bamboo flooring was environmentally friendly along with being so affordable until I read your article. I will be looking into switching my cheery wood floors into bamboo soon, as getting tired some same look. This information will be extremely helpful when I present this idea to the husband, who will be replacing the floor in the house.

Hi Jannette, Bamboo is a very sustainable and eco friendly product and has so many beneficial applications, with bamboo flooring just being one of them. I am sure you will enjoy your bamboo floor. Liné

Interesting article, I never knew that flooring products also can be made using Bamboo. I personally have a strong belief in green products. it will have a great future. Everyone should consider using Bamboo flooring when they build their new home. The world needs to be protected by all of us, in return the world will protect us too. Bamboo flooring will definitely be my first choice for my new dream home.

Bamboo floors are beautiful and would be my first choice in my dream home as well.

Although the process of making bamboo flooring can be stress and long but its really beautiful and gives the floor in your home a different look…Being a natural design rebranded to suit you taste the bamboo design is not like another so I do really recommend the bamboo flooring to you..nice post

Hi there, bamboo floors are indeed beautiful and easy to maintain. They come from a sustainable source and will enhace the look and ambience of any home.

Thanks for the post about bamboo flooring. I got so much by reading this blog. I think bamboo flooring is always around us. Sometimes, I don’t even recognise if its made out of bamboo and not other woods. Thanks for letting me know how to recognise that this type is made out of bamboo. I think it is very eco-friendly by using bamboo flooring in the house and its recyclable as well, which can help reduce a lot of waste.

Hi there, bamboo is indeed a very versatile plant with uses in textiles, furniture, the building industry and even cups and plates. Almost nothing gets wasted in the process and it is a sustainable natural plant.

Very interesting article. I never knew that bamboo was perennial. This certainly makes for an enviromentaly friendly product that is in high demand.I like reading about the manufacturing process of building materials and this is certainly a unique one for me. It seems as though not much of this harvest goes to waste either.

Hi Ricky, bamboo is indeed an amzing plant with many uses from clothes, to building applications and even household products like plates and cups. You are quite right that very little goes to waste when it comes to bamboo.

Fascinating! I had no idea how this product was made. I wish our world used more bamboo, since it is sustainable and renewable. Looking forward to more articles about the use of bamboo. Could this be a solution to some of the problems of our American farmers who no longer have a tobacco market? It might bear looking into.

Hi Fran, you can read another article on bamboo at this link https://ecoworldonline.com/why-choose-bamboo-fiber-products which I hope you will find interesting.

Other than the fact that bamboo flooring us always strong and very durable, it also gives a beautiful look to the general presentation of the home design. I like the process involved with it. I decided to read more concerning bamboo flooring since my new apartment is made from it and I wanted to be sure of how durable it is. The process of making it is simple and straightforward. But, isn’t there a way to curb companies making use of lesser quality products?

Like with most industries in this world, one cannot control them all. This applies to how bamboo flooring is made as well. We as consumers need to make sure that we ask and know what is in the products we are buying.